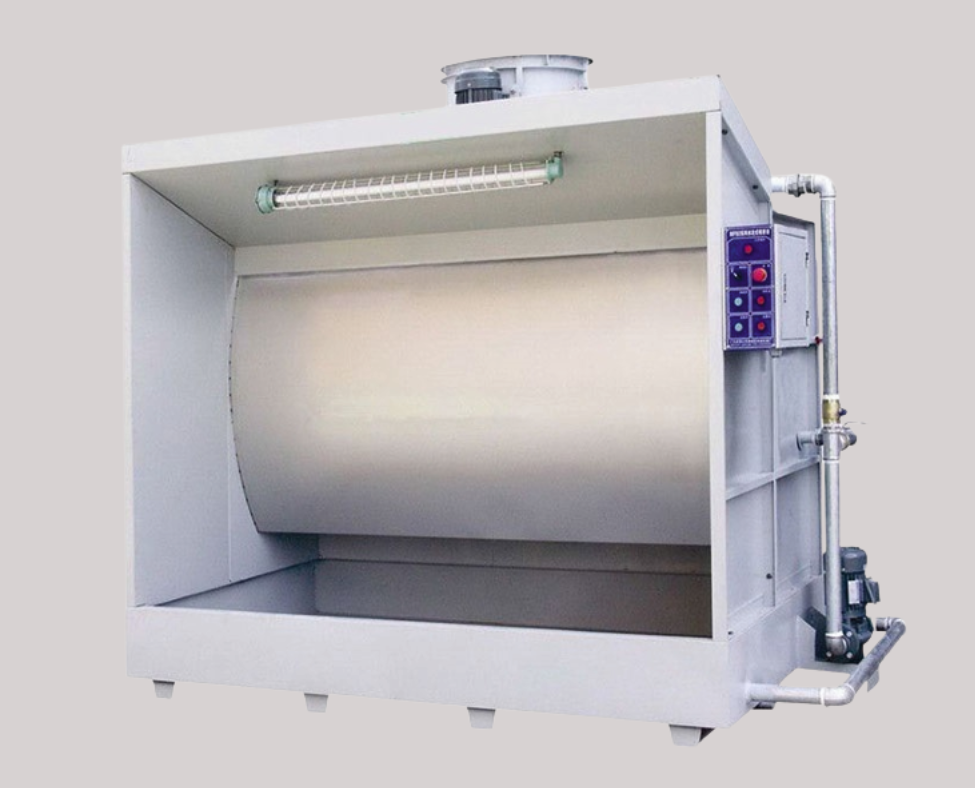

Water Spray Booth

Product Specification

| MODEL | FAN (HP/KW) | AIRFLOW (CMH) | NUMBER OF FANS | PUMP (HP/KW) | NUMBER OF PUMPS | WORKING BOOTH LENGTH MM | WORKING BOOTH HEIGHT MM | WORKING BOOTH DEPTH MM | OVERALL LENGTH MM | OVERALL HEIGHT MM |

|---|---|---|---|---|---|---|---|---|---|---|

| WSB - 20 | 2/1.5 | 5700 | 1 | 0.75/0.55 | 1 | 2000 | 2120 | 1050 | 2120 | 3100 |

| WSB - 25 | 3/2.2 | 7400 | 1 | 0.75/0.55 | 1 | 2500 | 2120 | 1050 | 2620 | 3220 |

| WSB - 30 | 5/3.7 | 9100 | 1 | 0.75/0.55 | 1 | 3000 | 2120 | 1050 | 3120 | 3440 |

| WSB - 40 | 2/1.5 | 10800 | 2 | 1/0.75 | 1 | 4000 | 2120 | 1050 | 4120 | 3100 |

| WSB - 50 | 3/2.2 | 14500 | 2 | 2/1.5 | 1 | 5000 | 2120 | 1050 | 5120 | 3220 |

| WSB - 60 | 5/3.7 | 18200 | 2 | 0.75/0.55 | 2 | 6000 | 2120 | 1050 | 6120 | 3440 |

This industrial system is designed for high-performance air filtration, safety, and durability in demanding work environments. The frontal modular veil ensures smooth airflow and easy access for servicing, while the drop separator efficiently removes heavier particles before they reach the filters. Metallic drawers fitted with a paint-stop filter capture overspray, ensuring cleaner air and longer filter life.

A centrifugal electrical fan with an IE2 motor delivers powerful yet energy-efficient airflow, supported by a stainless steel electrical immersion pump for long-lasting performance. The integrated water filter enhances particle capture, and the IP65-rated wired ceiling light provides bright, dust- and moisture-proof illumination. For safety and ease of operation, a wired electrical panel with an emergency start/stop button is included. The change section allows for quick and easy maintenance without disrupting workflow.

- Frontal Modular Veil – Improves airflow and offers easy service access.

- Drop Separator (Filler) – Removes heavy particles before filtration.

- Metallic Drawers with Paint-Stop Filter – Captures overspray for cleaner air.

- Centrifugal Electrical Fan with IE2 Motor – High efficiency and consistent airflow.

- Stainless Steel Electrical Immersion Pump – Corrosion-resistant and durable.

- Water Filter – Enhances filtration and protects system components.

- Wired Ceiling Light (IP65) – Bright, dust- and moisture-proof lighting.

- Wired Electrical Panel with Emergency Start/Stop – Ensures safety and easy operation.

- Change Section – Simplifies maintenance and filter replacement.

What is a Centralized Dust Collector?

A Centralized Dust Collector is an industrial system designed to collect dust and airborne particles from multiple machines or processing points through a common ducting system. Instead of having individual collectors for each machine, this system centralizes dust extraction, making it more efficient and easier to manage.

How does a Centralized Dust Collector work?

The system uses a powerful suction motor to pull dust-laden air through a network of ducts connected to different machines. The air passes through filter bags or cartridges where dust particles are trapped, and clean air is released back into the workspace or environment. Some models include automatic pulse-jet cleaning systems to keep filters clean and efficient.

How do I choose the right size or capacity?

Selection depends on:

Number of collection points

Type of dust (fine/coarse)

Required airflow (m³/hr or CFM)

Available space & layout

Is this system energy-efficient?

Yes, our collectors are built with high-efficiency motors and optimized airflow design to reduce energy consumption while maintaining powerful suction performance.

Can I integrate this dust collector with my existing machinery?

Yes, our systems are modular and customizable, and can be easily integrated into existing production lines with proper ducting and inlet layout.

Do you provide installation and support?

Absolutely. We provide on-site installation, commissioning, and post-sale support, including AMC (Annual Maintenance Contracts) if needed.